Sugar Cube Assembly

Revised 3/2018

I have encountered some rare issues with these types of speakers (not just mine). Fortunately, there are quick and easy resolutions to the problems.

1. The speaker sounds staticy at all volume levels

I have found a propensity for metal fragments from the workspace to find their way into the speaker. Metal fragments are all over the place, and are even more likely to populate the MRR workspace. The magnets in the sugar cube speakers a neodynium, and will absolutely pick up any ferrous material in the vicinity. You can remove most or all of the contamination by using another magnet. The only requirement is the other magnet must be fairly strong.

2. The speaker distorts at high volume, such as when you blow the horn

The primary purpose of the baffle, as stated in applicable literature to speakers of this kind, is to prevent the cancellation of sound. Covering one side prevents this phenomena. What is not well documented is the similarity with large speakers, which in some designs require sealed chambers to prevent the diaphragm from moving too much. This seems to be a factor in these extremely small speakers when you approach their sound pressure limits. To solve this issue you must make sure the baffle is sealed. Make sure to completely seal the joint where the speaker attaches to the baffle. Also, plug the gap around the wire holes in the baffle. I use white glue for all of this because it makes a great gap filler, yet is not as permanent in case I have to disassemble. If you have already glued the speaker, and suspect there to be air gaps, simply coat the surface of the seam with some while glue.

I have encountered some rare issues with these types of speakers (not just mine). Fortunately, there are quick and easy resolutions to the problems.

1. The speaker sounds staticy at all volume levels

I have found a propensity for metal fragments from the workspace to find their way into the speaker. Metal fragments are all over the place, and are even more likely to populate the MRR workspace. The magnets in the sugar cube speakers a neodynium, and will absolutely pick up any ferrous material in the vicinity. You can remove most or all of the contamination by using another magnet. The only requirement is the other magnet must be fairly strong.

2. The speaker distorts at high volume, such as when you blow the horn

The primary purpose of the baffle, as stated in applicable literature to speakers of this kind, is to prevent the cancellation of sound. Covering one side prevents this phenomena. What is not well documented is the similarity with large speakers, which in some designs require sealed chambers to prevent the diaphragm from moving too much. This seems to be a factor in these extremely small speakers when you approach their sound pressure limits. To solve this issue you must make sure the baffle is sealed. Make sure to completely seal the joint where the speaker attaches to the baffle. Also, plug the gap around the wire holes in the baffle. I use white glue for all of this because it makes a great gap filler, yet is not as permanent in case I have to disassemble. If you have already glued the speaker, and suspect there to be air gaps, simply coat the surface of the seam with some while glue.

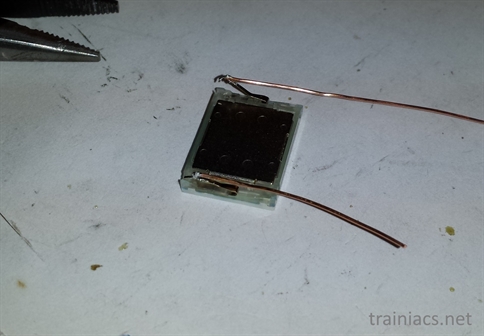

Step 1: Solder wire to the connector. I use small lengths of solid uninsulated wire. The magnet will want to grab your iron, so use a metal tool (such as a pair of needle-nose pliers) to hold it in place.

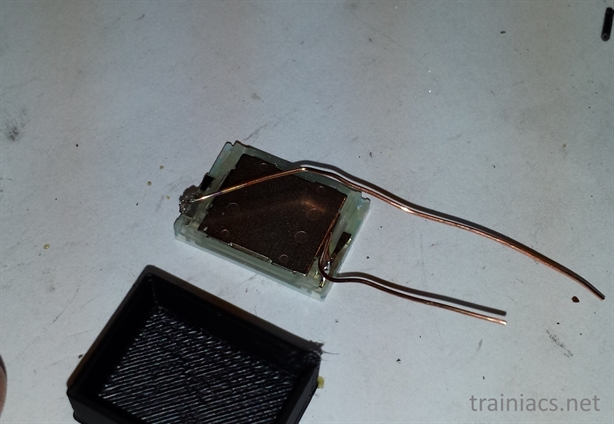

Step 2: Bend wires accordingly. Some speakers (pictured here) have contacts perpedicular to holes. Just make sure wires aren't touching each other or the metal back of the speaker. Solid wire helps because it stays where you put it.

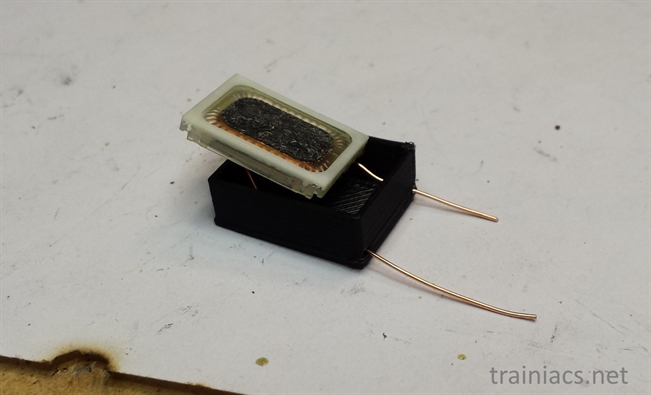

Step 3: Test fit

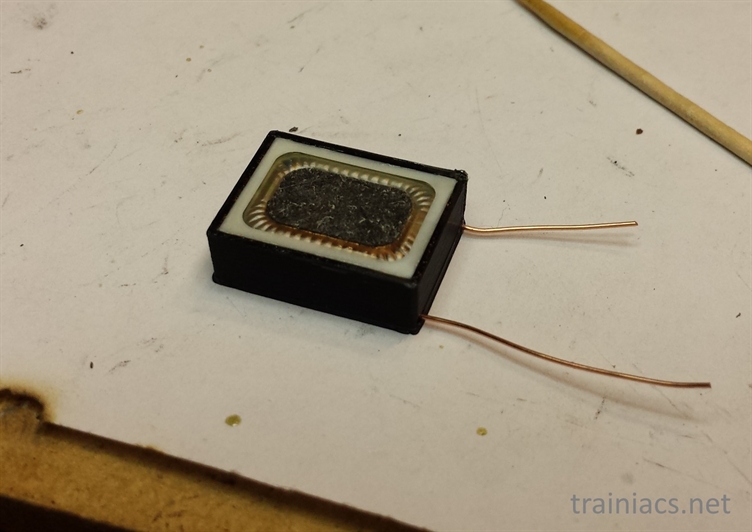

Step 4: Glue together.

You are done! Solder speaker wires from decoder to the wires on the speaker. Use heat shrink to protect from shorting.